The Box Flat Mine disaster on July 31, 1972, remains a poignant chapter in Australian mining history. In Ipswich, Queensland, a devastating explosion claimed 17 miners’ lives, echoing a stark reminder of the industry’s dangers. This tragedy became a catalyst for pivotal safety reforms, shaping the future of mining operations nationwide. The incident underscored the critical need for enhanced safety protocols and spurred legislative and technological advancements aimed at preventing similar tragedies. Today, the disaster serves as a solemn reminder and motivator, reinforcing the importance of prioritizing miner safety.

The Day of Tragedy: Unveiling the Box Flat Mine Disaster

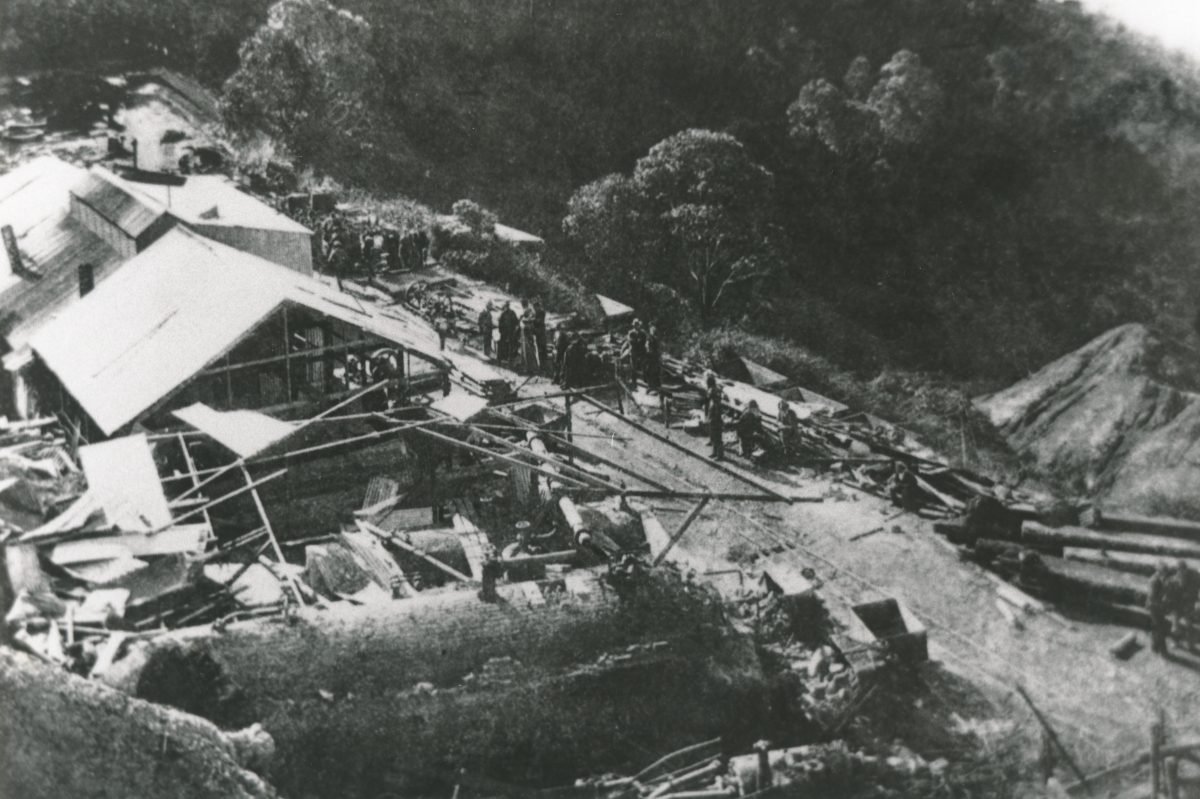

The Box Flat Mine in Ipswich, Queensland, became the site of a tragic event on July 31, 1972. Methane gas ignited, leading to a devastating explosion. Seventeen miners, beginning their shift, were instantly trapped by the blast. Hindered by lethal gas levels and precarious conditions, rescue operations struggled. The community, intertwined with mining, mourned deeply. Eventually, the decision to seal the mine was made, entombing those lost. This choice profoundly affected their families and the entire nation, revealing glaring safety oversights. It triggered a nationwide push for improved mining safety protocols.

Contributing Factors Behind the Explosion

Critical oversights set the stage for the Box Flat Mine disaster. Firstly, inadequate ventilation allowed dangerous levels of methane gas to accumulate. Methane, highly explosive when mixed with air, found its ignition source that fateful day. Additionally, the mine lacked sufficient gas detection systems. This shortfall meant that rising methane levels went unnoticed until it was too late. Furthermore, safety protocols were not robust enough to mitigate such risks. The miners were also working with equipment that could easily spark, igniting the methane-air mixture. Consequently, the explosion was both violent and unavoidable under these conditions. The aftermath highlighted the urgent need for comprehensive safety measures. This disaster served as a pivotal moment, driving significant changes in mining safety standards. It underscored the importance of rigorous monitoring and advanced safety practices in preventing future tragedies.

Post-Disaster Safety Reforms

In response to the tragedy, sweeping safety reforms were swiftly implemented. Enhanced ventilation requirements were established, ensuring a continuous flow of fresh air to dilute methane concentrations. Similarly, the introduction of advanced gas detection systems became mandatory, allowing for early warnings of hazardous gas buildups. Critically, these reforms mandated regular safety drills, preparing miners for emergency evacuations. Equipment and machinery were upgraded to include safety features that minimized the risk of sparking. Moreover, new legislation strengthened oversight of mining operations, focusing on risk assessment and management. These actions reflected a significant shift towards prioritizing miner safety above all. As a result, the mining industry saw a marked reduction in similar incidents. These changes not only honored those lost in the Box Flat Mine disaster but also set new safety benchmarks for mining worldwide.

Reflecting on Change and Remembrance

The Box Flat Mine disaster serves as a somber reminder of the risks inherent in mining. Yet, it also marks a turning point in mining safety standards. The tragedy spurred a collective call to action, leading to pivotal safety reforms that have since protected countless lives. Today, the mining industry continues to evolve, driven by technological advancements and a steadfast commitment to safety. The legacy of those lost in the disaster lives on, inspiring ongoing efforts to prevent future tragedies. As we remember the lives impacted, we also recognize the resilience and progress born from this dark chapter. The disaster’s lessons remain integral, guiding the industry towards a safer future for all miners.